Abstract

As the world transitions to more sustainable technologies it is no different in the electrical power industry and more specifically, in the Insulation fluids used in power transformers. This presents some challenges as this head-long rush to install more transformers, and retro-fill existing units, has outstripped the usual developmental learning curve where new technologies mature by a process of trial and error.

Introduction

For most transformer applications, mineral oil is an acceptable, cost-effective insulating fluid, and this situation is likely to continue well into the future. However, in applications where fire safety and protection of the environment are important considerations, transformers based on alternative fluids can be a more viable option.

The use of alternative fluids in transformers is not new technology; these fluids have been used for many years, mainly in distribution transformers. Lately there has been a clear trend to use these fluids at ever increasing voltages and power ratings, and now there are many examples of their use in high voltage and high-power transformers.

This article is designed to provide an overview of some advantages and limitations that exist for synthetic and natural esters. (Green Insulation Fluids)

Synthetic esters

Synthetic esters are used mainly in distribution transformers and in transformers where fire safety and environmental protection are a prime concern. They are increasingly being used in power transformers and in demanding conditions, such as traction, trackside and wind farms.

Unused synthetic esters are supplied in accordance with IEC 61099 and a maintenance guide is available as IEC 61203 Edition2.

Natural esters

Since the beginning of the 1990’s, because of increasing environmental concerns, companies started to develop vegetable oils as transformer fluids. These natural ester fluids have been commercially used since 1999.

Nowadays, natural esters are widely used in the distribution transformers.

Unused Natural esters are supplied in accordance with IEC 62770 Edition1, and a maintenance guide is available as IEC 62975 Edition1.

Note: The use of natural esters is recommended only for equipment that is not open to the atmosphere, e.g. sealed transformers and reactors, because these fluids are prone to rapid oxidation.

Physical and Chemical Differences between the Ester Fluids and Mineral Oil

An overview of the different properties of insulating liquids is presented in Table 1

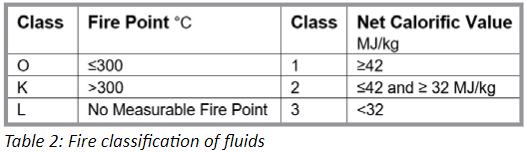

Fire classification for transformer fluids

The classification of insulating liquids is based upon Fire Point & Net Calorific Value according to the standard IEC 61100.

Advantages and Disadvantages

To date, there has been much research in both industry and academia to discover and document the properties and behaviour of these fluids, and the items discussed below are an attempt to help readers understand the complexities.

Advantages:

1. Natural esters are biodegradable and have a lower environmental impact compared to mineral oil. They are derived from renewable resources, making them more environmentally friendly.

2. Some synthetic esters are designed to be biodegradable, offering similar environmental benefits.

3. Natural esters: typically have higher fire points and are less flammable than mineral oil, contributing to improved fire safety.

4. Synthetic esters: depending on the specific type, synthetic esters can also offer improved fire safety characteristics.

5. Reduce the aging rate of the paper insulation.

6. Reduce the moisture content of the insulation paper, which improves the dielectric strength.

7. Eliminate bubble formation due to sudden overload, which reduces the risk of partial discharge.

8. Eliminate oil sludge formation, which improves the cooling efficiency.

Disadvantages:

1. Higher initial cost of ester fluids compared to mineral oil( ± 5 Times the price).

2. Compatibility issues with some materials such as paints, gaskets and seals.

3. Viscosity and pour-point issues at low temperatures.

4. Additional filtration or drying equipment to maintain the quality of ester fluids.

5. The regeneration (reclaiming) avenues and possibilities of the regeneration of esters are still a challenge that needs to be explored.

6. Possible need for additional testing and monitoring to ensure the performance and safety of retro-filled transformers.

7. The diagnostic for condition monitoring is not fully understood.

Design Considerations

The purpose of this section is to highlight the importance of viscosity in transformer design, along with other some other considerations.

The specific transformer design (everything from gasketing systems to LTC's, bushings and the cooling system performance) must be evaluated to determine suitability for a synthetic or natural ester. This is just one of the many things that must be evaluated in the design review.

Viscosity differences may cause the transformer power delivery rating to change. Also, oil preservation systems may need modification to deal with the oxidation characteristics of the ester fluid. Other considerations include bushing, tap changer and other components & systems.

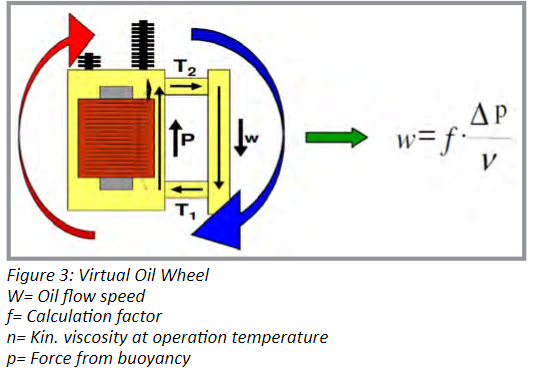

Virtual Oil Wheel (Viscosity)

Calculation of the natural oil circulation speed based on the Laws of Bernoulli, Newton, Reynolds and Prandtl.

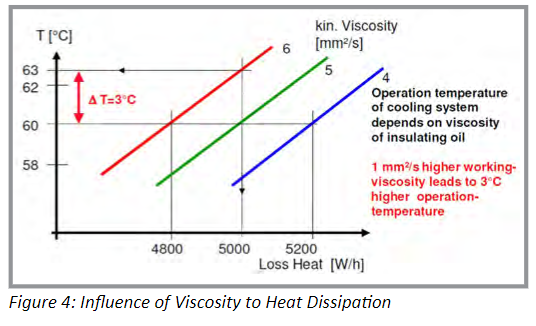

Influence of Viscosity to Heat Dissipation

Operation temperature of cooling system depends on viscosity of insulating oil, as ester fluids have much higher viscosities; this factor needs consideration in transformer design and the impact on retro filling.

1 mm²/s higher working viscosity leads to 3°C higher operation temperature.

Additive Question

Many esters contain additive packages consisting of chemicals, to reduce the pour point and aid in oxygen stability, and, in some cases, they have an antimicrobial agent or copper deactivators. This contrasts with mineral oil which has either no additives or merely oxidation inhibitors. It is not known if any adverse characteristics exist when esters are used in transformers over a long period.

Ideally these additives require monitoring, as with any additive package there will be depletion over time.

Furthermore, for compliance with IEC Standards the supplier, with mutual consent, should declare the generic types of all additives, and their concentrations, but unfortunately this far from the case.

Dissolved Gas Analysis (DGA) as a diagnostic tool

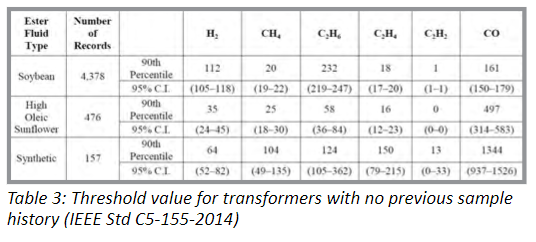

There is limited information published concerning the analysis of combustible gases in ester fluid, as the DGA data for mineral oil filled transformers is far greater than ester filled units.

IEEE and CIGRE have developed General Guidelines for the interpretation of gasses generated in ester-immersed transformers.

It’s recommended to establish base line data when a new transformer is first placed in service.

A weekly or monthly DGA analysis is recommended when a transformer is energised on load to establish the Gas Generation rates (Rates of Gas rise).

Note: The interpretation of DGA is empirical in nature, and the most widely used methods, for fluid insulated transformers are based on the identification of key gases and various gas concentration ratios. Threshold concentrations for each of the key gases and for the total fault gas concentration must also be empirically established.

Since industry looks to companies for diagnostic solutions and technical knowledge, we devote time and resources to research and development; furthermore, through our participation in IEC and CIGRE, we have been able to adapt to the challenges in understanding the dynamics of ester fluids for the benefit of our clients. (As per the following case study).

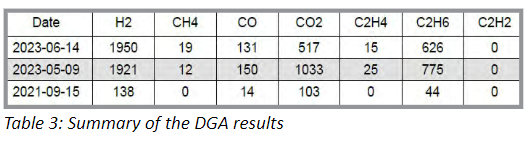

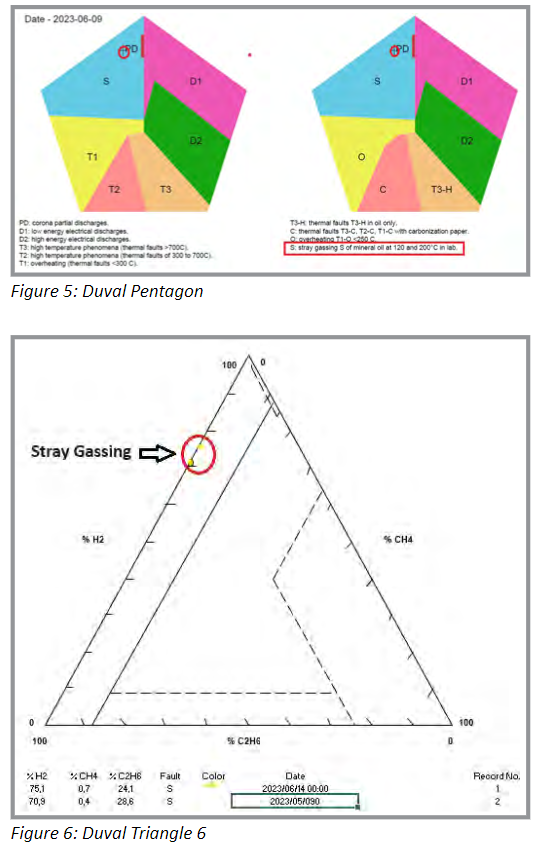

Case Study 1: 132 kV Main Transformer located at a Data Centre

The case of a 30 MVA,132 kV transformer, with an OLTC. Manufactured in 2021 and designed for a natural ester insulating fluid.

We were tasked with providing an expert 2nd opinion on the DGA results as the initial testing laboratory had diagnosed this transformer with a high temperature fault, with the recommendation to remove from service for Inspection and repairs.

It was requested that a further sample be taken to confirm the results from the other laboratory.

Although the DGA levels exceed the IEEE Std C57.155-2014 threshold values, the gas rates of rise are not significant for a natural ester, and the correctly applied Duval Triangles and Pentagons showed stray gassing (No fault condition).

Retro-filling

Before deciding to retrofit a transformer, it is crucial to conduct a thorough analysis, considering factors such as cost, environmental impact, safety, and compatibility with existing equipment. Consulting with transformer manufacturers and experts in the field is advisable to ensure a successful and effective retrofit.

Based on experience of manufacturer and operator, the following concerns regarding dielectric behavior, thermal design, material compatibility and ester approved components should be discussed prior to the use of ester liquid in a transformer application.

Draining and flushing cannot remove all the dielectric liquid from a transformer, particularly from insulating paper. The cellulose (paper) insulation can hold as much as 10% of the total volume of the nameplate litres.

Over time the leach-back of mineral oil could lower the fire point to less than specification.

A design review for the specific transformer should be conducted by someone competent who can determine the impact of replacing mineral oil with an ester fluid.

Note: This requires a holistic approach not limited to fire safety and environmental issues.

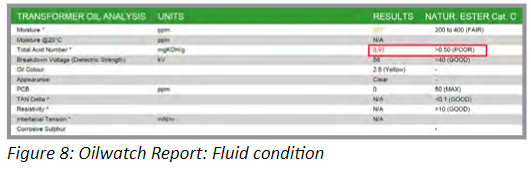

Case Study 2: 11 kV plant transformer located at mine

The case of a 630 KVA transformer (Category C), manufactured in 2005 and retro-filled with a natural ester insulating fluid, approximately one year prior to a routine oil test. The oil had deteriorated (oxidised) within a year to a state that replacement was required.

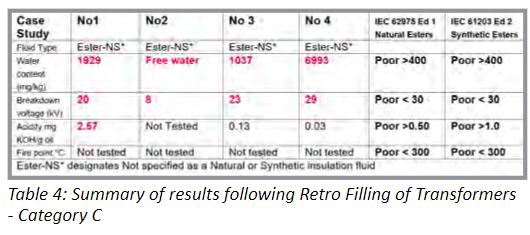

Case studies following retro-filling

Table 4 provides a summary of results following retro-filling of transformers: Category C. Note: The above data are not specifically Oilwatch results - supplied by clients and are a reflection on the issues related to retro-filling.

Challenges facing Southern Africa

It is envisaged that the future will see an increasing growth in the use of these fluids in evermore challenging and higher power applications, as the knowledge and experience of their benefits become more commonplace.

Major transformer manufacturers and end users are keen to promote the use of these fluids, especially where the advantages they have over mineral oil, such as fire safety, can be usefully employed as a mineral oil substitute in sensitive areas.

However local transformer manufactures need to be mindful; a system can only be as reliable as the reliability inherently built into its design.

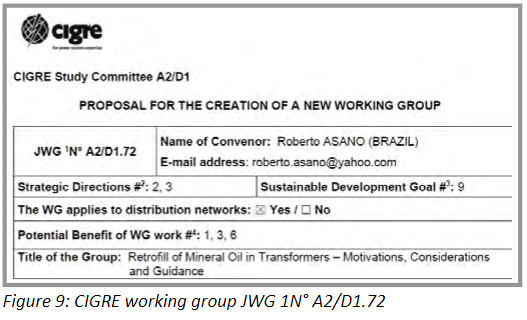

Recognised international bodies such as CIGRE, IEEE and the IEC now have several working groups dedicated to furthering the knowledge and application of these fluids.

CIGRE are forming a new working group (Retro-fill of mineral oil in transformers – motivations, considerations and guidance), which is long overdue.

In the meantime, it might be prudent to wait for the working group to complete its work and rather concentrate on sound predictive/reliability-centered maintenance of the existing mineral oil transformers.

About Ian Gray

Ian Gray is a member of the South African Chemical Institute and the South Africa mirror committee for IEC TC 10(International Electro technical Commission)/CIGRE (SA-Regional Advisory Group). He also serves on the SANS 290 committee (Mineral insulating oils - Management of polychlorinated biphenyls (PCBs). His over-35 years of experience includes transformer oil testing, diagnostics and internal inspections coupled with the ISO17025 quality management system.

Normative References (Abridged)

- CIGRE TB 436, TB 443, Study Committee A2/P2-ID11064

- IEC 61099 / 61203Ed2 / 62770 / 62975

- IEEE C57.147-2006 / C57.147-2008 / C57.155-2014