Renewable energy generation plants in solar, wind and storage systems have specific requirements:

- Installation in environmentally sensitive locations

- Reduce outages causing production and profit losses

- Relieve cost-reduction pressure

- Address loading patterns with extremely high variations (including harmonics content)

- Mitigate potential stresses due to vacuum or gas switches

FR3 fluid transformers help meet all these requirements.

Environment and operational safety

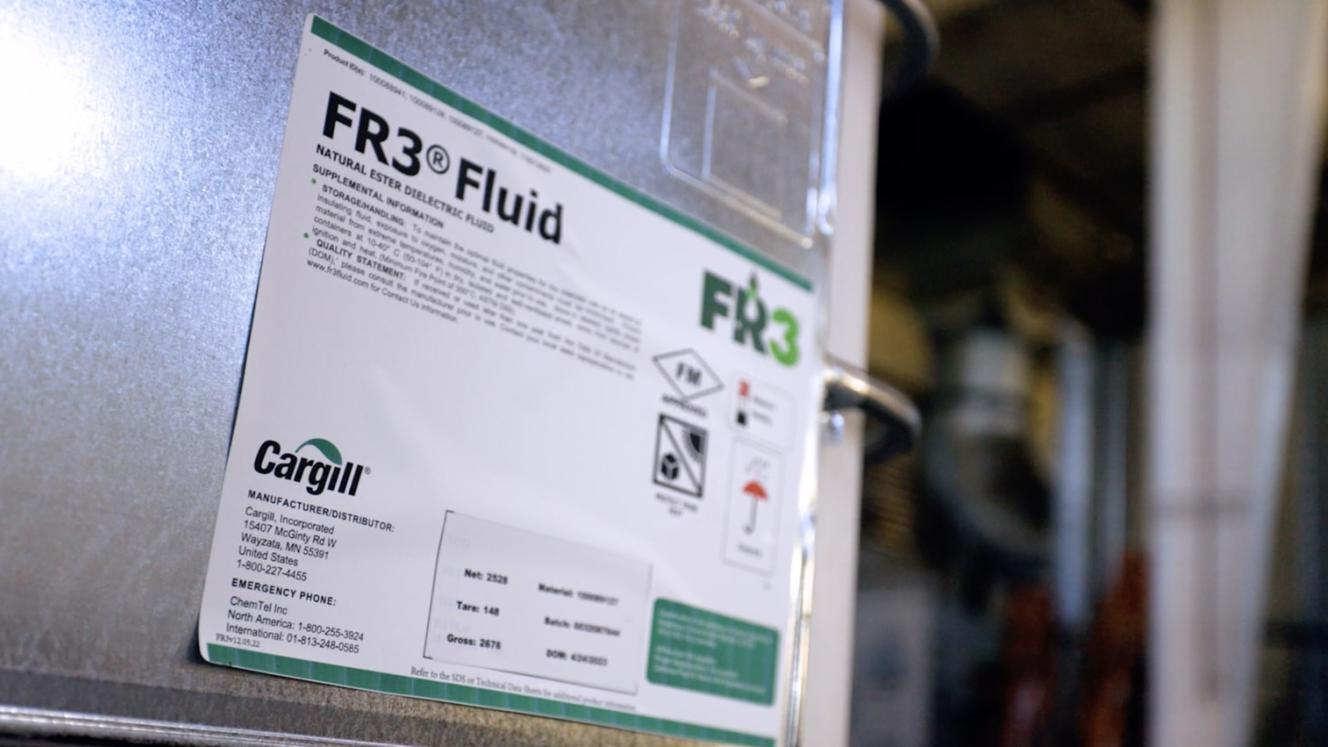

FR3 fluid is non-toxic in water and soil and +98% bio-based. It surpasses the requirements of ultimate and ready biodegradability. The high fire point qualifies it as a K-class fluid with FM Global Approval and UL listing as EOUV and EOVK. Beyond this, it offers a record of zero reported pool fires.

More compact transformers

Often installed in “skid units” of solar installations or inside packed nacelle spaces in wind farms, high output from a small unit can provide tangible benefits for nearly all renewable energy applications.

FR3 fluid-filled units, designed for traditional temperature limits, can feature an additional continuous loading capacity of +25% to +50% above the high-temperature rise limits of IEC 60076-14 and IEEE C57.154 standards.

Alternatively, transformers built with FR3 fluid and traditional thermally upgraded paper can be classified as high-temperature insulation systems with “nominal life” at temperature limits of thermal class 140. This enables:

- Higher loading capacity with potential to reduce transformer size and weight

- Peace of mind with mitigated fire risk, lower environmental impact (in comparison to the standard mineral oil solution) and reduced fluid-related maintenance

Increased reliability

FR3 fluid has a higher water saturation point, which (combined with the ability to consume water by hydrolysis) keeps insulating paper dry throughout transformer life. Besides increasing the thermal class of the insulation system, it also preserves the dielectric capacity of the insulation system as the transformer ages without the need for related maintenance outages.

Sealed transformers filled with FR3 fluid remain dry, which increases reliability while mitigating the need for moisture removal interventions and minimising sludge formation.

In addition, FR3 fluid’s higher partial discharge inception voltage has been found to reduce partial discharge activity and its associated combustible gases caused by inverter high-frequency voltage harmonics in mineral oil-filled step-up inverter transformers.

Higher nameplate capacity

Traditionally, the transformer nameplate capacity is chosen to meet peak demand as overloading mineral oil units is associated with increased risks. This is not the case for FR3 fluid-filled units. Enabling safe above-nameplate loading capacity changes this paradigm.

By setting transformer rated capacity to match typical demand, instead of peak demand, the initial investment and size – as well as the operational efficiency of the transformer – can be optimised.

Click here for more information.