Information from Siemens Energy

The foundation for a sustainable future

Energy is the beginning of everything, the basis of civilisational development and the foundation of all economic progress. To make it future proof, we need a balance of affordability, reliability, and sustainability. This includes a phase-out of coal, the expansion of renewables, the further development of hydrogen-capable gas power plants and grid stability services, as well as storage solutions that step in when the wind isn’t blowing, and the sun isn’t shining. Together, these steps and technologies can ensure energy security and make a decarbonised energy system possible.

Decarbonising South Africa’s power generation: What can take coal’s place?

Today, the world is tackling climate change with a growing sense of urgency. At last year’s COP27 in Sharm El Sheik, Egypt and despite the war in Europe, and the ongoing business disruptions caused by fragility of the supply chain, there is a sense of optimism. Siemens Energy has the products and tools to drive towards a carbon neutral power generation and make it a reality.

"South Africa with its vast reliance on coal fired power generation, needs a more diversified energy mix and a massive expansion of renewable energies along with corresponding infrastructures and storage capacities. The long-term phase out of coal is an important first step." - Thabo Molekoa, Chairman and Managing Director, Siemens Energy South Africa

This article aims to show that advanced combined cycle power plant running on natural gas as a transitional fuel and on green hydrogen, or any mixture of those two gases later, are the key element for South Africa on its individual road to deliver reliable and affordable electricity generation whilst making huge steps towards decarbonisation of its power generation industry.

Not every country’s solution will be the same since every country’s starting point is different. Coal has been the mainstay of the South African energy system, meeting around 90% of installed power generation capacity. The 2019 Integrated Resource Plan, however, sets out a long-term diversification of the power mix by 2030 and moves towards reducing the carbon footprint of the energy sector while meeting growing energy demand and ensuring a socio-economically just transition [2].

Replacing coal fired power plants purely by intermittent renewables, like wind or solar, will not work on its own. We lose not only balancing and dispatchable power, but also grid stability. Support with batteries is currently limited to a short period only. Compared to advanced gas turbines in combined cycle, alternatives such as reciprocating engines consume high amounts of lube oil and generate highest amounts of nitrogen oxides (NOx).

For a good comparison of the emission footprint of dispatchable gas-based power generation technologies, a very recent study from the VGB (International Association for Electricity and Heat supply) organisation is available [3]. The future for South Africa’s electricity generation will be a renewable based electricity system, supported by batteries for the short term and combined cycle power plants ensuring the stamina for providing continuous reliability.

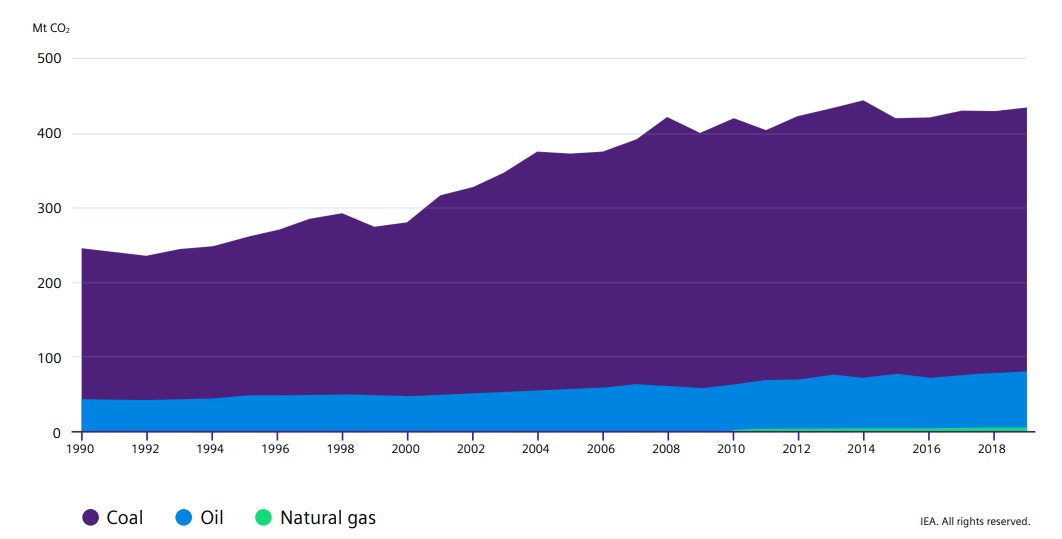

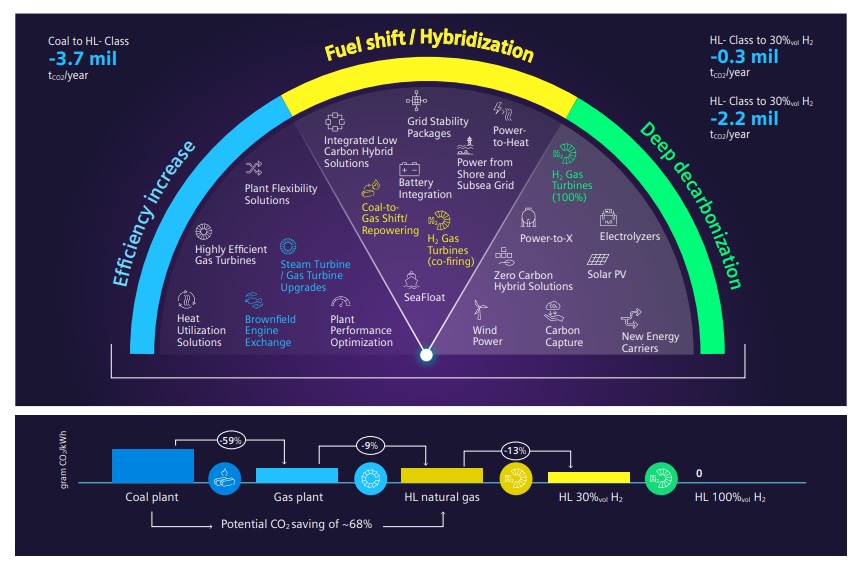

The objective for gas turbine based dispatchable power is a net-zero footprint when operated on green hydrogen in the near future. So, what are the immediate steps for South Africa to reduce its carbon dioxide (CO₂) emissions? As mentioned above and reflected in IEA's image (Figure 1), the biggest and fastest lever would be to move away from the coal fired generation towards a hydrogen ready gas turbine combined cycle technology. By doing so, the immediate impact on the CO₂ emissions would be up to 70% reduction (Figure 2).

This of course is like a marathon run, rather than a sprint. As the renewable generation capacity slowly increases, now is the time to take concrete measures for the needed support generation capacity. As a first concrete step, the work on the planned 3000 MW Eskom combined cycle power plant in Richards Bay and the Department of Mineral Resources and Energy’s 3000 MW Independent Power Producers (IPP) plants should start immediately, replacing ageing coal units and giving assistance to the grid for shouldering more renewable generation.

For today and tomorrow: Role of proven technology and innovation

In most market scenarios, by 2030 the rising energy demand will largely be met by the accelerated expansion of renewables, namely solar and wind. Whereas in 2020, worldwide renewables were responsible for 30% of electricity generation, their share is projected to increase by about 45% in 2030 based on announced national pledges [4]. At the same time, as more renewables are added to the system there’ll be an immediate need to supply balancing and dispatchable power along with grid stability to balance the renewable (e.g., wind, solar) fluctuations.

Once dispatchable power is provided, the share of renewables can grow even further. The power may mainly come from gas turbine combined cycle power plants (CCPP) increasingly running on clean fuels, such as hydrogen not only at the utility scale, but also mid to small size, when it comes to industrial applications. And given the current geopolitical climate, we can expect an accelerated transition. The gas turbine technology, although more than 70 years old, is far away from becoming obsolete.

The energy density of a gas turbine is unmatched by any other conventional electricity generation process. As large as a bus, as heavy as an airplane this piece of heavy metal is far from being outdated. In the past decades remarkable technology advancements have been made. The breaking of the 60% efficiency barrier by Siemens Energy in the 2010’s unleashed a strong momentum to develop a new set of skills, tools, and materials, such as 3D printing of prior unthinkable geometries, e.g., for burners or new coating materials for blades and vanes.

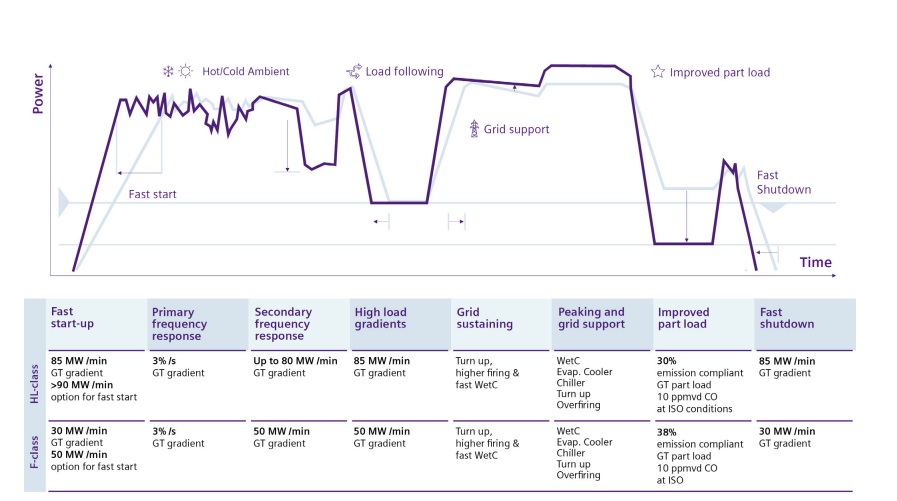

Now even the 63% efficiency barrier has been passed. Furthermore, the operational flexibility, e.g., ramp rates of the gas turbine, have also advanced thanks to a new generation of AI based control systems and enhanced design features like variable inlet guide vanes. Many operators in Europe are using their CCPP in daily start stop and cycling mode. In Figure 3, a typical “day in the life” of an advanced gas turbine is shown. During morning time, the gas turbine can ramp up very fast and then enter a grid operator following mode offering various frequency response mechanism for balancing out load demand or even switching-on power augmentation measures, when loss of generation capacity somewhere else needs compensation. This is of course all performed within the frame of emission compliance ensuring single digit nitrogen oxides (NOx).

When the day is coming to an end, the gas turbine can ramp down fast or, if requested, can serve the electricity demand during night times. Importantly, all the above can be done automatically with a fully integrated combined cycle power plant, where the steam turbine acts as a companion to the gas turbine, offering further spinning services and co-start capabilities.

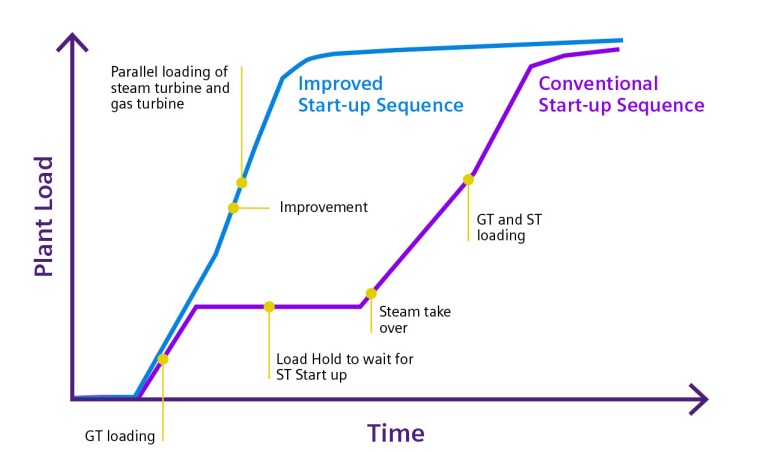

In the past, startup times for combined cycle power plant (CCPP) were largely viewed as slow, mainly due to the holding/waiting time governed by the need to thoroughly warm steam turbine casings and valves. Modern plant design, however, implements certain measures to ensure a parallel start (co-start) of the gas turbine and the steam turbine is possible (Figure 4) without penalties. These measures include features like, heat recovery steam generator (HRSG) damper, auxiliary steam support, steam stress controller and many more.

When the CCPP has been shut down for less than eight hours, for example due to an overnight shutdown, an immediate restart early in the morning, or the following day, is possible. Around 30 minutes after the plant-restart process has been initiated, allows the turbine to complement fluctuating renewables like never before, meeting power demands when wind or solar power can’t. The unit also helped achieve the Guinness World Records title for most powerful single cycle gas power plant [5] with an output of 410,9 MW, enough to power more than 300 000 homes.

References for coal-to-gas shift: Moving to zero CO₂ emissions

Replacing coal capacity with highly efficient H₂-ready CCPPs Combined cycle power plants (CCPP) operating on the available fuels (e.g., natural gas, liquid natural gas (LNG), liquid petroleum gas (LPG), etc.) and on green hydrogen are the right technology to replace coal-based power generation. To make the up to 70% reduction of carbon dioxide (CO₂) more tangible, we have selected two references. A new CCPP in Komotini, in the northeast of Greece, is expected to achieve savings of up to 3,7 million tons per year [7].

Furthermore, the infrastructure around shutting down coal plants can be wisely used to switch to a highly efficient hydrogen-ready CCPP. This conversion is known as a full repowering, and not only does it facilitate the repurposing of existing assets, but it also has the potential to lower investment costs when compared to a greenfield project. Moreover, repurposing existing assets involves shorter implementation times, less paperwork, and fewer permits.

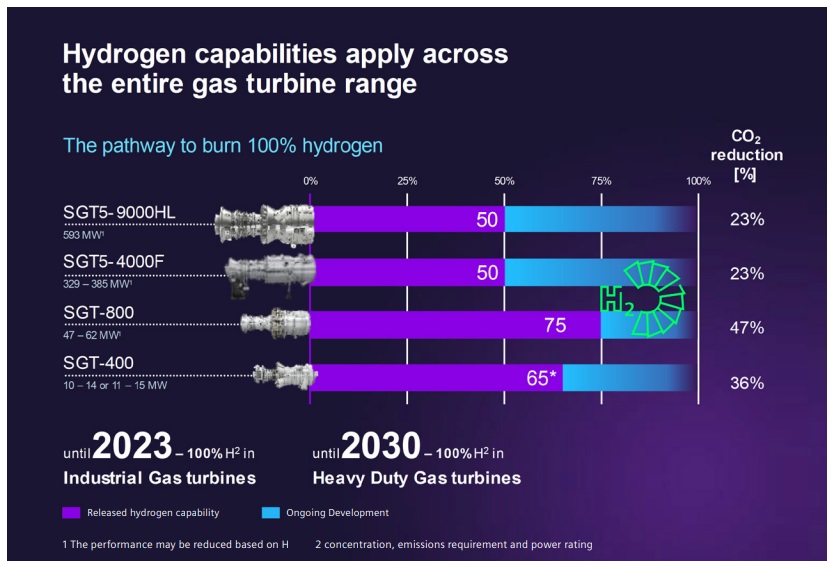

Apart from reducing CO₂ emissions, this also leads to an increased efficiency from an average of 38% up to 63%. However, this is not only related to power plants, as the example from an industrial coal-to-gas shift in Marl, Germany shows [6]. Future-proofing gas power plants with hydrogen Future-proofing gas power plants means equipping them with turbines that are capable of co-firing clean fuels, mainly hydrogen or other e-fuels. Today, many major gas turbine OEMs, including Siemens Energy, have turbines capable of operating with a mixture of 30 to 70% hydrogen, and are working toward 100% hydrogen by 2030 (Figure 5). Unsurprisingly, most customers in Europe want their gas power plants to be hydrogen-ready. To address this demand, as of 2021, TÜV Süd in Germany offers hydrogen-ready power plant concept certification and Siemens Energy has been the first company to receive it [8].

Maintaining grid stability: Building an energy transition bedrock

With the transition to renewables as a main source of energy generation, grid stability is at risk, as renewable power adds no inertia to the grid. As a result, the risk of load shedding increases. South Africa has a complex electricity infrastructure. Some of the old coal power plants, which need to be shut down for economic and ecological reasons may, still have existing permits, a good grid connection and operable generators. These sites could be kept operational on a smaller footprint and become repurposed for grid services, thus mitigating the socio-economic impact on the communities.

Inertia, something highly appreciated with electrical engineers and grids It’s no surprise that rotating masses as a standalone solution are already being added in grids with a high share of renewables. In Europe, especially at former power plants, Rotating Grid Stabilisers (RGSs) are being installed by converting existing generators. The result is a large piece of spinning machinery, which can also operate as a synchronous condenser and is usually combined with a flywheel.

When connected to the grid, a gas turbine provides inertia by spinning continuously without generating any power. It contributes to the stability of the system by spinning in sync with the grid frequency and dampening fluctuations, just as car shock absorbers dampen the impact of a bump in the road. In addition, RGSs support voltage stability by providing reactive power and enhance grid strength at connection points by providing short circuit power. And they are designed to respond instantly, without delay. As a result, RGSs make it possible to avoid stranded assets and contribute to a decarbonised energy system.

Voltage control over long distances

Rotating Grid Stabilisers (RGSs) aren’t the only option for helping maintain grid stability. Over long distances, it’s particularly difficult to maintain high voltage control with intermittent renewables, such as wind and solar, which supply the bulk of renewable electricity. As their supply can fluctuate, it’s necessary to sustain voltage control. A reactive electronic solution is a static VAR compensator (SVCs). Instead of a spinning mass, they use power electronics. They help operators avoid blackouts caused by excessive loads and surges, insufficient voltage, or natural catastrophes that might take out parts of the grid.

Additionally, it takes smart control systems to manage a complex grid facing an increasing share of renewables and the corresponding fluctuating power flow, decentralisation of production, and ever-increasing energy demands. These controls require higher capabilities beyond monitoring, controlling, and automation systems. They need to be intelligent and able to react quickly to changing conditions, such as weather, varying energy demand and supply, and so on. Moreover, smart systems like these don’t just help maintain reliable power distribution, they also help operate power plants in cost efficient ways and with the smallest possible carbon footprint. This can be realised, for instance, by ramping up energy generation when demand is high and slowing it down when it’s low. Siemens Energy is the reliable partner to manage these scenarios.

The social impact: Ensuring a just energy transition

Another important aspect of changing the complete energy system is its social impact. Globally, millions of jobs will be lost at coal power stations, associated mines, and oil and gas companies. And this doesn’t just affect people’s material livelihoods. Work is also a matter of personal identity for many people, even for entire regions. Therefore, while advocating for decarbonisation, it’s important to see how, for example, clean energy technologies may help provide local employment in future-proof jobs.

It is time for South Africa to build combined cycle power plants to compliment planned and underway renewable programmes, to acquire a new set of skills and reach the next level of industrial and socio-economic development. To do it right, many new jobs will be created in clean energy, which is projected to generate more jobs than those being lost in the coal industry [11]. These jobs will be available in green energy generation, energy-efficiency measures for buildings, and manufacturing.

The World Energy Outlook estimates that compared to today, another 13 million workers should be employed in the clean energy sector, given the current energy policies and government pledges worldwide [12]. Likewise, a recent McKinsey report found that in Europe, “the net-zero transition would create an estimated 11 million jobs, while eliminating six million, resulting in a net gain of five million jobs” [13].

These changes will be accompanied by various government programs, for example, the transferring of qualified personnel from the fossil fuel industries to other new energy sectors, such as renewables, carbon capture technologies, and hydrogen production, among others. For example, the United Kingdom has a North Sea Transition Deal (NSTD) in place that aims to “support and anchor the expert supply chain that has built up around oil and gas in the UK, to both safeguard and create new high-quality jobs” [14].

Other countries around the globe are engaging in similar initiatives. For South Africa, it is vital to understand the impact of the Just Energy Transition on the country’s Socio-Economic Development. A just energy transition should enable workers, climate-vulnerable, and disadvantaged communities to access decent work and sustainable livelihoods within a new green economy. As its commitment to South Africa, Siemens Energy is heavily invested in continued education and training in the country, through initiatives such as bursaries, hackathons, and a power academy. The firm’s power academy will train 450-500 students per year on sustainable energy technologies.

References

1 “The evidence is clear: the time for action is now. We can halve emissions by 2030”; Press Release, IPCC, April 4, 22.

2. World Energy Outlook 2021, IEA, p. 125

3. https://www.vgbe.energy/wp-content/uploads/2022/09/vgbe-ej-2022-07-032-047-SIEKER.pdf

4. World Energy Outlook 2021, IEA, p. 125.

5. Siemens Energy and Duke Energy’s gas power plant achieves GUINNESS WORLD RECORDS™ Press Release, Siemens Energy, August 23, 2022.

6. “A million tons of CO2 lighter”; May 2021, Siemens Energy.

7. “Siemens Energy’s HL-class technology enables Greece to reduce CO₂ emissions and protect the environment”; Press Release, Siemens Energy, September 30, 2020.

8. “Siemens Energy is the first manufacturer to receive certification for “H₂-Ready” power plant concept”; Press Release, Siemens Energy, November 16, 2021.

9. “Siemens Energy’s grid stabiliser technology to help Irish grid exceed renewables penetration limit“; Press Release, Siemens Energy, May 4, 2021.

10. “World’s first mobile STATCOM: When grid stabilisation gets wheels”; Siemens Energy Magazine, May 23, 2018.

11. World Energy Outlook 2021, IEA. p. 54.

12. World Energy Outlook 2021, IEA. p. 54.

13. “How the European Union could achieve net-zero emissions at net-zero cost”; Report, McKinsey Sustainability, December 2020.

14. “North Sea Transition Deal”; Policy Paper, March 24, 2021.

Contact Mark van Antwerp, Siemens Energy, mark.vanantwerp@siemens-energy.com