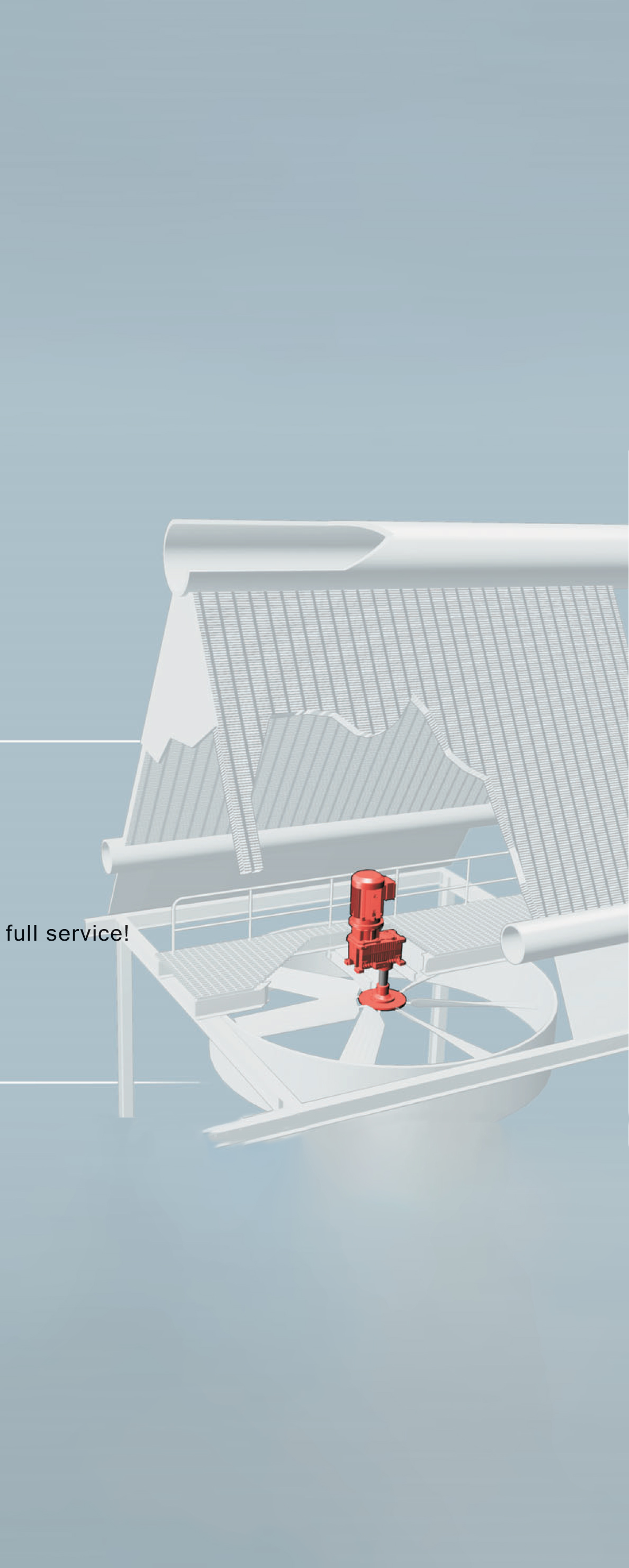

Recently installed in a power station, 24 of SEW-Eurodrive’s MACC-Series two-stage gear units for air-cooled condensers are ensuring adequate air movement to cool circulating water so that power generation can continue.

This cooling function had become a challenge for the power station when existing products from a different supplier kept failing. SEW-Eurodrive had installed MACC units elsewhere in the power station previously, and their reliable operation led to a request to supply several additional units to replace those which kept failing. According to the company’s business development representative Quintin Bianchina, their design is specific to this demanding application.

With the fan in operation, there is both upward and downward thrust as well as forces to the left and right. The flat topography and climatic conditions around the power station also exacerbate the situation, especially on hot days when air moves rapidly up the cooling towers. The gearbox, bearings, and shaft must be designed and manufactured to accommodate these forces while continuing to operate reliably.

The noise levels are an additional factor in this application, and the quiet MACC units ensure that they do not exceed maximum limits; the customer monitors the noise to check compliance. Heat build-up in the gearbox must also be dissipated, so the design includes cooling ribs to increase the surface area. This design enhances the cooling significantly on the gear units. A low-noise axial cooling fan is also available as an option for enhanced thermal performance.

Another vital aspect of the product’s features is the maintenance safety brake on the high-speed input section of the gearbox. This can be applied to bring the fan safely and easily to a standstill under windmilling conditions when maintenance is required. Due to their size, these fans do not usually stop turning once they start – due to the natural upward airflow into the cooling tower.

Now that the firm has recently built a new and expanded facility at Aeroton in Gauteng, the assembly of these MACC units can be done locally. Enlarged stockholdings of components means that the turnaround time will be drastically reduced from 30 or more weeks for imported units, to 8 to 12 weeks.

Contact SEW-Eurodrive South Africa, www.sew-eurodrive.co.za

Linkedin – www.linkedin.com/company/SEW-EURODRIVE-sa/

Facebook - www.facebook.com/SEWEurodriveSA

YouTube - www.youtube.com/user/SewEurodriveTV