In August 2022, Marthinusen & Coutts Zambia was requested by a smelter based in the Copperbelt to provide an in-country repair solution on two critical 4,5MW compressor motors. The firm was given only three weeks in which to overhaul and commission the motors.

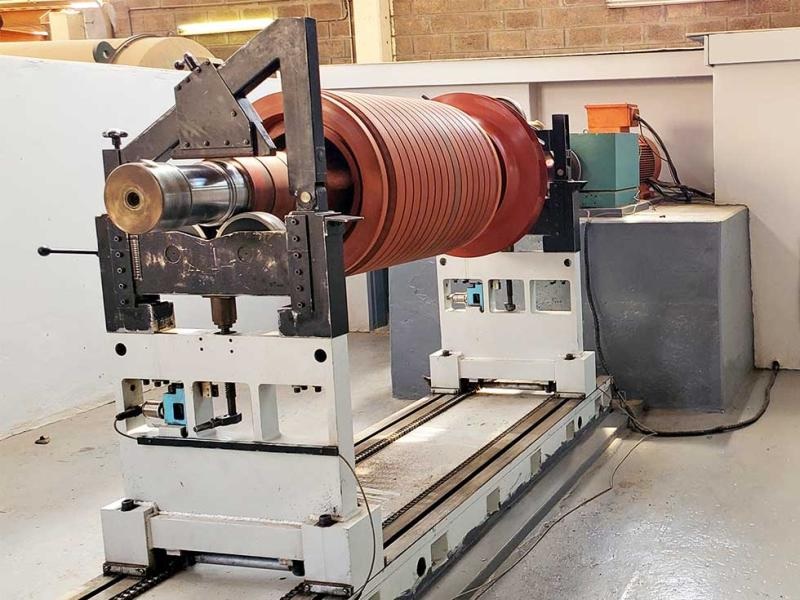

The scope of work involved was to dismantle, clean and assess all parts, dynamically balance the rotors at operating speed using M&C Zambia’s own 12 t balancing machine, supply new bearing assembly parts, assemble the motors and no-load test and laser align the motors on site.

Eugene Lottering, M&C Zambia’s General Manager, explains that upon dismantling both motors the team identified that the stator coils indicated partial discharge and the stator wedges had deteriorated significantly over time. Consequently, the company’s workshop in Cleveland, Johannesburg supplied partial discharge treatment for the stator coils and manufactured the stator wedges that needed to be replaced.

To ensure that that all the work complied with international standards, M&C also sent a senior technician from Johannesburg to assist the local team on the contract.

The company’s team is well experienced in how to approach and action various stages throughout the overhaul of these motors, having successfully completed various medium voltage overhauls up to 4650 kW. The motors were no-load tested at 11 kV with exceptionally good results and the customer then gave the firm the go-ahead to commission the motors. The motors were finally tested on load, recording satisfactory vibration levels of below 1,34 mm per second.

Although installing them on site turned out to be a complicated procedure, especially the alignment of the motors to the compressors, were successfully installed and commissioned three days before the scheduled deadline for completion, Lottering said.

Contact support@mandc.co.za