In response to the escalating demand for advanced power semiconductor modules, Japanese company NGK Insulators plans to ramp up production capacity of its AMB substrates.

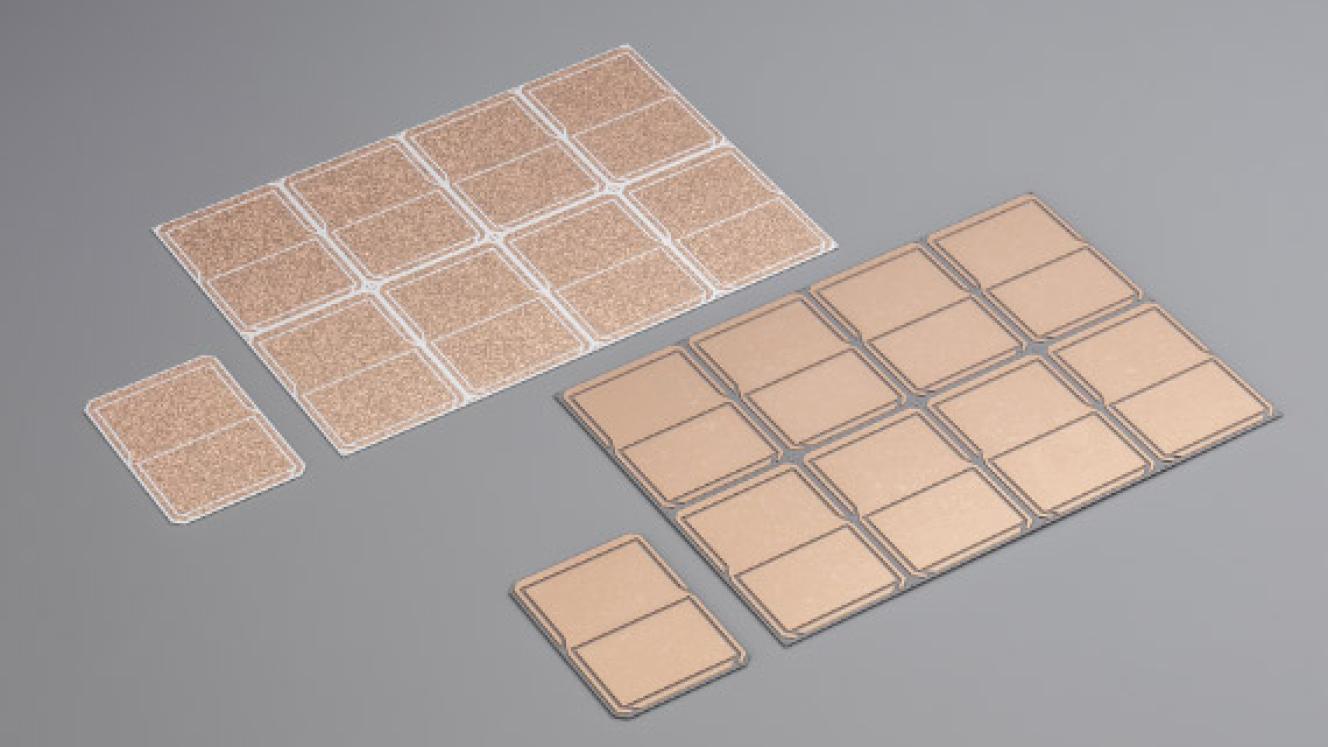

These substrates, crucial components in power modules, are crafted from Silicon Nitride and are instrumental in various applications such as motor drive control and power conversion.

By fiscal year 2026, NGK anticipates increasing the monthly production capacity from around 100 000 to approximately 250 000 AMB substrates.

The company is also planning an additional production base in Europe.

Since their introduction in 2019, NGK's Silicon Nitride AMB substrates have gained traction among several European and Japanese power module manufacturers.

“AMB substrates are comprised of a ceramic plate made of nitride-based material and two copper plates. Using NGK’s proprietary, advanced bonding technology, it is possible to make the bonding layers between the ceramic and copper with an extremely thin structure of just a few microns. This greatly reduces the thermal resistance and internal strain in the bonding layer, resulting in high reliability and excellent thermal dissipation characteristics,” says NGK Insulators.