Information from Megger

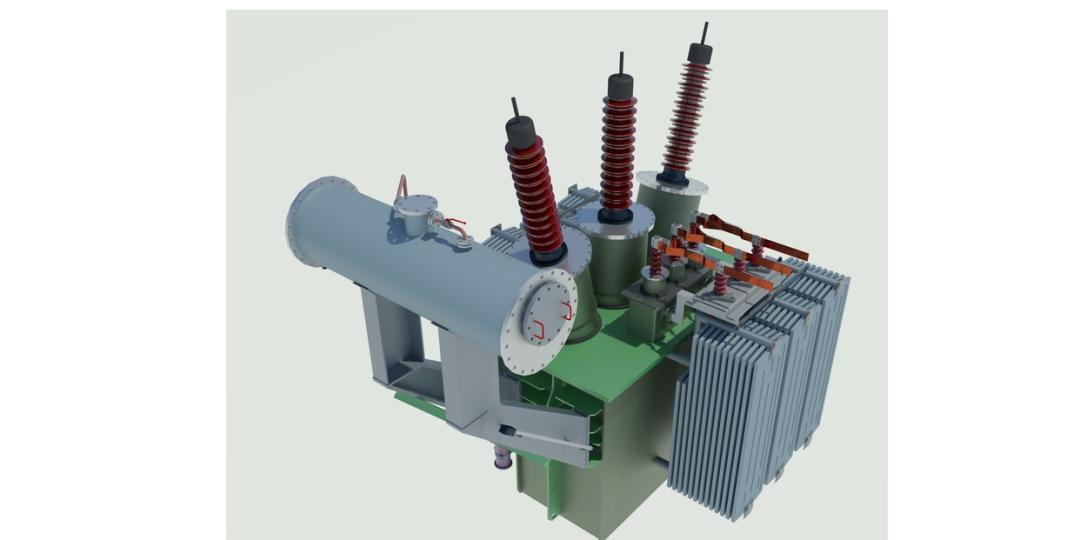

This article deals with the testing of 69 kV bushings which are installed on a 10 MVA, 69/13,09 kV Dyn1 two-winding transformer. After completing on-load tap changer (OLTC) maintenance on this 1969-vintage transformer, the utility owner conducted electrical tests.

Overall transformer line frequency power factor (LF PF) tests

Losses measured for the low-to-ground (CLG) and high-to-ground (CHG) insulation systems were higher than those measured for the interwinding, or high-to-low (CHL), insulation system of the transformer. The temperature-corrected (i.e., 20°C equivalent) LF PF test results for CLG and CHG insulation components were within acceptable limits (< 0,5%) and even within limits established for new transformers. However, the CHG LF PF test result (at 0,43 %) was approximately 1,8 times the CHL LF PF result (0,24%) (Table 1).

Based on recent experiences using Narrowband Dielectric Frequency Response (NB DFR) testing and successes in finding hidden issues not observed by LF PF tests, a NB DFR test was carried out. A NB DFR test is the measurement of PF (%) or DF (%) at different frequencies between 1 Hz and 505 Hz.

In addition, the testing specialist performed 10 kV C1 LF PF tests on the transformer’s high-side winding bushings (Table 2). The H3 bushing produced elevated LF PF test results (measured and temperature-corrected) which were notably greater than results for the sister bushings mounted on the same transformer. Accordingly, the individual temperature corrected LF PF test results for bushings H1 and H2 earned the bushings good (G) ratings while the individual temperature corrected LF PF test result for bushing H3 resulted in an ageing (A) assessment.

The test results also display an interesting anomaly in the ‘individual temperature correction’ values. A temperature-correction (TC) factor is used to determine a test specimen’s 20°C equivalent LF PF value when the specimen is power-factor tested at a non-20°C temperature.

An ITC factor is a TC factor which is unique to every test specimen as it is based on the specimen’s specific condition. Note that the ITC factor for bushing H3 (about 0,6) is different than the ITC factors determined for bushings H1 and H2 (about 1,04). The non-uniformity which exists in these ITC factors is a clear indication that the H3 bushing has a different insulation condition than H1 and H2 bushings.

Transformer bushing C1 test investigation

ITC factors are far more accurate than TC factors accessed in a look-up table. To underscore the problem with temperature-correction look-up tables, consider the following:

- If the end-user had relied on correction tables, the TC factor would have been determined based upon the average of the ambient and bushing temperatures. This would have resulted in a TC factor close to unity for all three bushings – valid for bushings H1 and H2 but not for H3.

- Bushing H3 would have been removed in this scenario due to a >1% PF value. However, had the bushing been tested at 10°C instead of at approximately 30°C, its measured and temperature-corrected PF test results by look-up tables may have been low enough to pass acceptance criteria as a normal, service-aged unit.

Given the LF PF test results, the utility performed NB DFR tests on the high-side bushings. 1 Hz and 505 Hz measurements from this testing are provided in Table 2. These tabular results affirm the good condition and rating of bushings H1 and H2 but escalate the assessment of the H3 bushing to an ‘investigate’ rating. NB DFR test results for bushing H3 (the blue trace in Figure 1) revealed the following two worrisome electrical characteristics so the utility replaced the bushing:

- A bushing in good condition will have an ITC temperature-corrected PF value ≤1% at 1 Hz. The ITC temperature-corrected 1 Hz PF test result of bushing H3 was 7,92 % (Table 2).

- The 10 kV LF PF test result, 1,1% (Table 2), and the LF PF test result at 250 V, a typical NB DFR test voltage, taken from Figure 1, 0,8%, are different. This implies a voltage dependence of the LF PF test results.

Before installing in the transformer, LF PF and NB DFR testing was performed on the H3 replacement bushing to confirm its integrity. LF PF and NB DFR test results indicated the bushing’s good (G) condition (Table 3 and Figure 2). After replacing the H3 bushing, the utility repeated the overall LF PF tests on the transformer to observe what effect the H3 bushing replacement had on the overall HV winding insulation test characteristics (Table 4). A notable improvement was observed.

With the problem corrected in the overall winding insulation test results, the utility staff then complemented their now routine procedure with a 10 kV LF PF test on the installed H3 replacement bushing (Table 5).

The 10 kV measured LF PF test result for the H3 replacement bushing was acceptable. However, the ITC temperature-corrected LF PF result is about 1,5 times the measured value while the 1 Hz measured and ITC temperature-corrected results are nearly the same; and the 505 Hz PF test result is both non-typical and notably higher than the 505 Hz PF test results for the H1 and H2 bushings.

NB DFR tests for the installed H3 replacement bushing revealed a non-typical response, with uncharacteristically high losses in the high frequency range (blue curve in Figure 3).

The data implicated the connection integrity of the bushing flange to the grounded tank. To verify the suspected grounding problem, the testing specialist applied a ground strap to the bushing flange and repeated the LF PF and NB DFR tests (Table 6). A significant improvement was observed in the LF PF test results and the dielectric response with the ground strap in use (green curve in Figure 3).

It should be noted that the field test specialist had no prior experience with detecting poor flange grounding. When presented with the probable cause of this 505 Hz anomaly, the specialist used a multimeter and measured the resistance between the tank ground and bushing flange with no notice of a resistance issue. Only with the use of a four-terminal low resistance test instrument was the specialist able to detect a ‘before and after’ difference. This underscores the exceptional sensitivity of a NB DFR test to insufficient bushing grounding.

The NB DFR curves of the original H3 bushing, the H3 replacement bushing before installation, after installation with poor grounding and finally in its ‘as left’ condition after restoring a good ground connection, are shown in Figure 4.

This provides a striking visual reminder of how bad the original bushing was, how practical NB DFR is for post-installation verification, and what the DFR curve for a bushing in good condition should look like.

Takeaways

- LF PF testing is the primary approach to evaluating HV insulation. Significant differences between UST and GST measurements may require further investigation. Bushings constitute part of the overall GST measurement of a transformer and therefore may be a factor in an elevated winding-to-ground LF PF test result. Megger recommends always testing bushings equipped with a test tap or potential tap.

- Temperature-correction look-up tables are not accurate for bushings with compromised insulation. The only reliable way to access the true, equivalent value of LF PF at 20°C is to determine the test specimen’s ITC factor.

- NB DFR in the range from 1 Hz to 505 Hz confirms both early and advanced degradation in bushing insulation.

- After a bushing installation, NB DFR testing is recommended as a verification procedure to detect poor grounding.

- PF test results at 1 Hz and 505 Hz for bushings in particular carry significant meaning and, as Megger’s Vince Oppedisano enthuses, is the “microscope” of insulation testing.

Contact Marie-Claude Rasendra, Megger, marie-claude.rasendra@megger.com