by John Evans BSc, MLA II, WearCheck

The quality of the diesel in South Africa is often a topic of hot debate. One of the first things to identify is what we mean by “quality diesel” – let us not confuse poor quality with dirty, wet or adulterated fuel. It is extremely unlikely that a single drop of diesel leaving South Africa’s refineries does not conform to the SANS standard for the quality of diesel. It is from this point that the problems start, with poor transport methods, poor handling, sloppy storage and corruption. A wide variety of engine problems can be traced back to contaminated diesel.

When determining diesel quality, it is important to use a laboratory that employs the correct test methods as dictated by the standard. It is also important to use a laboratory that is accredited by the South African National Accreditation System (SANAS) 17025 and the South African Bureau of Standards (SABS) ISO 9001. This ensures that the tests are carried out correctly, quality standards are met, and the results are reliable.

This article discusses the tests to determine diesel quality that are carried out in WearCheck’s Specialty Laboratory, the instrumentation used and what the consequences of failing to meet the standard might be, along with the actual limits that are applied.

Flashpoint

The flashpoint temperature of diesel is the minimum temperature at which the fuel will ignite on the application of an ignition source (naked flame). Flashpoint varies inversely with the fuel’s volatility. The SANS requirement is a minimum flashpoint of 55ºC.

The flashpoint of the fuel does not directly affect the combustion characteristics of the engine, but is important in terms of safe storage and handling - the lower the flashpoint, the more flammable the fuel is. A low flashpoint can help identify petrol adulteration, because for every ½ percent addition of petrol, we would see an approximate 8ºC drop in the flashpoint. Other contaminants - such as paraffin, other fuels and solvents - will also lower the flashpoint. Contamination with heavier fuels and lubricants will raise the flashpoint.

Viscosity

Viscosity is a measure of a fluid’s resistance to flow. It therefore affects injector lubrication and fuel atomisation. Fuels with low viscosity may not provide sufficient lubrication for the precision fit of fuel injection pumps or injector plungers, resulting in increased wear or leakage. High viscosity fuels, on the other hand, will increase gear train, cam and follower wear on the fuel pump assembly due to the higher injection pressures.

Diesel fuels with high viscosity also tend to form larger droplets on injection, causing poor combustion and increased smoke and emissions. Fuels that do not meet viscosity requirements lead to loss of performance. Again, this test would help identify both thin (petrol) and thick (oil) adulterants. The SANS requirement is 2.0 – 5,3 centistokes.

Viscosity is measured by the length of time it takes for the diesel to flow through a calibrated tube under the force of gravity at 40ºC.

Density

This is a measure of the specific gravity of the fuel, in other words, how much does a litre of fuel weigh? Both volume and mass are measured to determine density. Density essentially determines the energy content of the fuel. The denser the fuel, the more power the engine can generate, and vice versa. Diesel is specified at a minimum of 0,800 kg/l at 20ºC (the density at 15ºC is also determined). This helps to identify adulterants such as IP, which has a density of 0,790 kg/l. or oil, which has an approximate density of 0,885 kg/l. Low density fuel leads to a loss of power per litre of fuel and an increase in fuel consumption. Density and viscosity are actually measured on the same instrument.

Sulphur

This measurement helps identify what a diesel sample is not rather than what it is. Low sulphur diesel is specified at 0,005% (50 ppm) or less, while normal diesel is 0,05% (500 ppm). This specification only determines the maximum allowable level of sulphur in diesel – it does not mean that 50 ppm diesel has exactly 50 ppm sulphur and the same would apply to 500 ppm diesel.

Contamination of 500 ppm diesel with 50 ppm diesel results in the actual sulphur content varying between 50 and 500 ppm in practice. Concentrations of less than 50 ppm are also frequently noted. In the SANS 342 document, these two fuel grades fall under what is called CF1 (clean fuels). If you read the document, you will note that there is also a CF2 requirement, which covers ultra-low sulphur fuel at 10 ppm. Although this forms part of the specification, CF2 is yet to be legislated. Legislation had been planned for September 2023, but has now been postponed to July 2026. The main reason for this is that the modification to refineries to produce 10 ppm fuel is prohibitively expensive.

Sulphur is a naturally occurring constituent of crude oil, but its presence in diesel is an area of concern. The sulphur content of diesel can either be reduced by using low sulphur crudes or during the refining process, which is expensive. There is a range of valid reasons for the removal of sulphur from our diesel supplies. The first and most pressing reason is that high-sulphur diesels are known to influence the emission of fine particulate matter through the formation of sulphates. These particulates are considered a health hazard, and their reduction is desirable. However, the presence of sulphur must not be confused with dirty diesel; it is a vital component of diesel in that it imparts a natural lubricity, protecting fuel pumps and injectors. When this is removed during refining, it has to be replaced with additives to perform the same function.

High-sulphur fuel also produces sulphur oxides on combustion which, when dissolved in other by-products of combustion such as water, form strong acids. When these acids condense, they attack the metal surfaces of valve guides, cylinder liners and bearings. The acids produced are neutralised by the engine lubricant and, in doing so, reduce the working life of the lubricant, necessitating shorter drain intervals.

There are, however, steps that can be taken to reduce the damage that can be caused by burning high-sulphur fuel:

- Know the sulphur content of your fuel. It is recommended that every bulk delivery is checked, especially if fuel quality is questionable.

- Keep the normal operating temperature of the cooling system above 80ºC; this will limit condensation of sulphuric acids on cylinder liner walls.

- Select oils with a sufficient starting TBN (Total Base Number).

- Follow standard oil-change regimes unless oil sampling indicates differently.

- Maintain the crankcase breather system to prevent condensation in the crankcase oil, which will cause rapid TBN depletion.

Finally, high-sulphur fuels act as poisons to catalytic converters and other systems which are used in diesel engines to reduce exhaust emissions and reduce pollution.

Sulphur is measured by X-ray fluorescence spectroscopy. It is important to use such an instrument, as other instruments and spectroscopic techniques such as ICP are not valid test methods for the measurement of sulphur in diesel. Sulphur can be measured in either ppm or percentage; 1% is equivalent to 10 000 ppm (think of percentage as a part per hundred).

Distillation

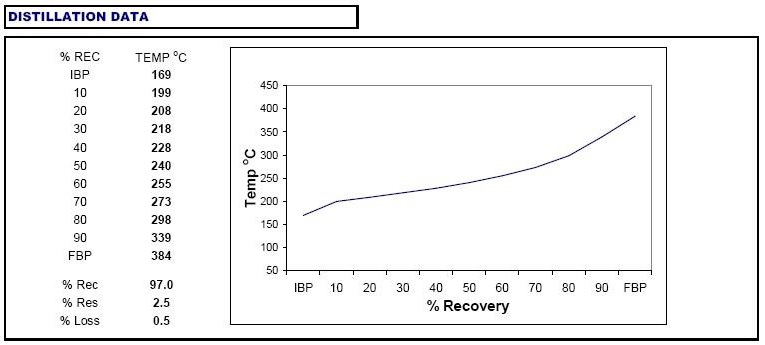

This test measures the temperature range over which a fuel turns to vapour. Volatility is one of the primary methods which distinguishes various fuels from one another.

It is also an indication of the fuel’s ability to start the engine, its power, fuel economy, emissions and deposit formation. In the laboratory, the point at which the diesel starts to boil is measured (IBP), the temperature at which the first 10% by volume has distilled over (T10), 20% has distilled over (T20) and so on up to 100% (T100) or the final boiling point FBP.

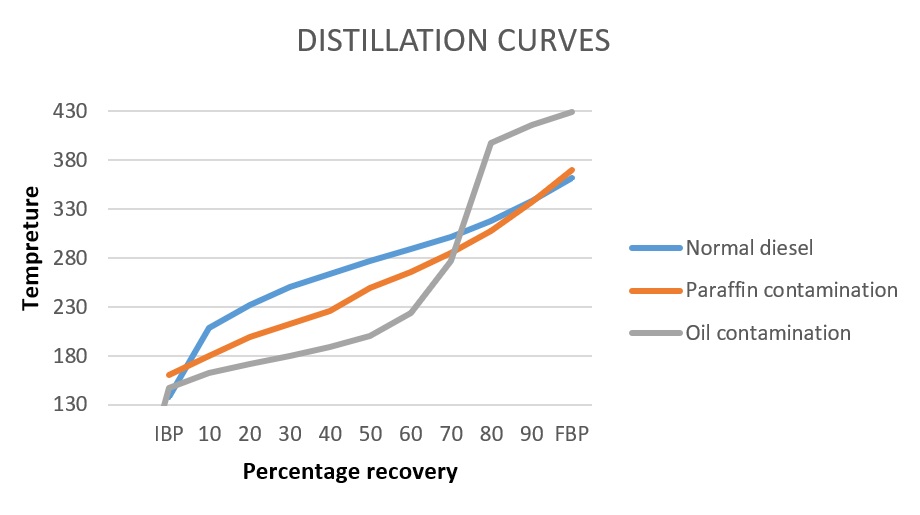

Distillation is specified at a maximum of 362ºC for T90 or 90% recovery, in other words, 90% of the fuel has boiled off. If the percentage distilled is plotted against the temperature, a characteristic distillation curve is produced. Any deviations suggest contamination.

In Figure 2 below, the blue line reflects a normal diesel curve, the grey line shows potential oil contamination, while the orange line depicts potential paraffin contamination.

Water

Water causes corrosion and reduces the ability of the diesel to act as a lubricant. Very small amounts of water can actually dissolve in diesel, and the maximum allowable amount of water is 350 ppm. It is important to note that water can exist in fuel in two forms – dissolved and free. The dissolved water is measured with a Karl Fischer titrator, which is an automated, electrochemical method for determining the amount of water very accurately.

Free water is assessed by examining a beaker of the fuel on a special light tray that shows up free water droplets very easily. The presence of free water is also grounds for the diesel to fail SANS 342. Note that it is quite possible for the fuel under test to pass one test whilst failing the other. The presence of free water, whilst passing the dissolved water specification, is usually an indication of contamination whilst taking the sample.

Total contamination

This test is used to determine the amount of ‘dirt’ or particulate matter in the diesel. The maximum amount of particulate matter allowed in diesel is 24 mg of dirt per kg of fuel.

Testing involves filtering one litre of sample through a pre-weighed 0,7 micron filter. The filter is then dried in an oven to constant weight. The difference in weight before and after is a measurement of the amount of solid particulate contamination in the sample.

This test is known as IP440. The IP does not stand for ‘illuminating paraffin’ as many people think; in this case, IP stands for Institute of Petroleum, test method 440.

The presence of particulate matter in diesel is a source of abrasive material that can cause wear and damage to the components in the fuel system, such as pumps and injectors. This is the only approved method for total contamination.

Cetane number (index)

The cetane number is a measure of the ignition quality of the diesel. It represents the time delay between injection and ignition. If the cetane number is too high, the fuel will ignite too close to the injector. This forms a fuel-rich region whilst the rest of the chamber has a weak fuel-to-air ratio. Incomplete combustion and soot formation will be the result.

Low-cetane fuels cause knock, difficult starting, rougher running and increased exhaust emissions. For typical on- and off-highway engines, a cetane number of 45-50 is considered ideal and is specified at a minimum of 45 in SANS 342 (but is generally found to be around 48). Illuminating paraffin has a cetane index of around 40 and will therefore affect the cetane number and performance of the diesel.

The cetane number can be determined by expensive testing in an engine laboratory. However, WearCheck has a more cost-efficient test method - we determine the cetane index of the fuel using an ASTM method utilising the distillation values T10, T50, T90 and the density of the fuel at 15ºC and 20ºC.

Visual assessment of the fuel

This involves placing a beaker of fuel on a light tray and making a visual observation. The fuel is checked for free water (as discussed under water analysis), free particulate matter (visible to the naked eye) and the clarity of the diesel.

Any free water, particulate matter or haziness would be grounds for the fuel to fail SANS 342. Note that, as with the water test, it is possible for a sample to pass either the total contamination or the visual assessment but fail the other. The colour of the diesel is also noted.

Fungal and bacterial testing

As the name suggests, a sample of diesel is tested for the presence of a range of bacteria and fungi.

This is a time-consuming process and involves adding a portion of the diesel to a special testing strip containing a medium that is ideal for the growth of ‘bugs’. This is then incubated for 72 hours in an oven. The growth of bugs over this period of time is rated against a chart and given a very slight, slight, moderate or heavy concentration of bacteria and/or fungi classification.

Essentially, this may allow us to identify problem areas; it would then be up to the operator to take corrective action such as dosing the bulk tanks with a biocide. The amount of contamination is rated in cfu/ml, colony-forming units per millilitre.

Bacteria and fungi can grow in diesel, particularly if there is water contamination. The microbes live at the fuel/ water interface and can form foul-smelling mats that can clog filters and produce acids that would be damaging to fuel-system components. Note that SANS 342 does not provide a limit on this sort of contamination, as it is not part of the specification.

Biodiesel

Biodiesel is diesel manufactured from renewable organic sources, traditionally vegetable oils (biomass) and is considered to be an alternative, environmentally friendly source of power. Biodiesel can be used as a pure source for internal combustion engines. It can also be blended with ordinary fossil fuels (diesel). SANS 342 allows a maximum biodiesel content of 5% (B5). Biodiesel content is measured using Fourier Transform Infra-red spectroscopy (FTIR).

Total acid number (TAN)

The TAN of diesel can be measured using an electrochemical titration and gives an indication of the overall acidity of the fuel, however, it does not form part of the SANS 342 specification

Particle counting (ISO 4406)

Particle counting by ISO 4406 can be carried out and used as another indication of fuel cleanliness. A sample of fuel is passed through a test cell and is illuminated by a laser, the various particles cast shadows on a detector and the number of particles per ml in various size ranges can be measured. The three size ranges are greater than 4, 6 and 14 microns. The total number of particles in each size range can be converted into a guide number for each size range and expressed as an ISO 4406 cleanliness rating (such as 18/16/13): the lower this is, the cleaner the fuel is.

ISO 4406 and particle counting do not form part of the SANS 342 specification, so no limit is given. However, there is an international body called the Worldwide Fuel Charter. The Worldwide Fuel Charter was first established in 1998 to promote a greater understanding of the fuel-quality needs of motor-vehicle technologies and to harmonise fuel quality worldwide in accordance with vehicle needs.

The Charter gives an upper-limit recommendation for ISO 4406 of 18/16/13. Although there is no legal requirement for South African diesel to meet this recommendation, many OEMs are very interested in these numbers, which is why WearCheck carries out the test.

Particle counting on diesel is very difficult to carry out because the viscosity of diesel is so low. This means that particulate matter settles very quickly in the sample. The standard method of particle counting used on lubricating oils cannot be used on diesel. A special test method (ASTM D7619) exists specifically for the purpose of measuring the cleanliness of fuels and this is what must be used.

Other tests

There are quite a few other tests that form part of the SANS 342 specification, these are not carried out by WearCheck, but can easily be outsourced. These include copper corrosion, calorific values, cold filter plugging point (CFPP), cloud point, lubricity, carbon residue, ash and oxidation stability.

The range of tests that WearCheck offers on its standard SANS 342:2016 report covers a wide range of analyses that encompass the most common and day-to-day requirements of diesel testing. The cost of doing everything that is listed in the specification would make the cost of a fuel sample prohibitively expensive, however, the other tests can be provided on request

Illuminating paraffin

No article on diesel testing would be complete without some discussion on the problem of diesel being contaminated with illuminating paraffin.

In response to an article that appeared in Fin 24 on 15 June 2022, Gwede Mantashe, the South African Minister of Mineral Resources and Energy, warned of the use of illuminating paraffin to ‘doctor’ diesel in an attempt to defraud the revenue services and increase profits. The following discussion gives a bit of background to this practice, the deleterious effects it can have, and the various methods for testing diesel for the presence of illuminating paraffin (IP).

Diesel can be subjected to a variety of chemical and physical tests in the fuel laboratory. One of the most common and important things to look for is contaminants, the most common of which are dirt and water.

Diesel can also be contaminated with other fuels and solvents, in particular illuminating paraffin, or IP, as it is known. IP is a readily available power source for domestic lighting, heating and cooking. Chemically, it is very similar to diesel, but because it is used as a domestic power source, it is not subjected to the taxes and levies that diesel is, in other words, it is cheaper than diesel.

The less-than-honest members of our society have taken to doping diesel with IP and, because it is so similar to (but not exactly the same as) diesel, a diesel engine will run quite happily on a diesel/IP mixture at less than the cost of diesel. Although the engine will run without a problem in the short term, in the long term, the IP will be quite damaging to the engine. IP has a lower viscosity and less lubricity than diesel, and will cause damage in terms of increased wear to the components of the fuel system.

Although the price difference may not be huge, if you think of the thousands of litres of diesel used every day, doping diesel with 10 or 20% paraffin represents a large cost saving and loss of revenue for the country’s revenue services (SARS).

The effects of IP contamination on diesel are that the viscosity, density and flashpoint will decrease, and the sulphur concentration will increase. Low density means you get less bang for your buck (more litres of fuel required for the same number of kilometres travelled). Low flashpoint could become a safety issue, and elevated sulphur could impact the emission controls of modern engines and increase combustion by-products being introduced into the lubricating oil. This will reduce its ability to lubricate the engine adequately, resulting in shortened drain intervals.

Interestingly enough, small amounts of IP may not affect the properties of diesel enough for it to fail SABS specification SANS 342, so, IP can be present, yet the fuel will still pass the specifications of SANS 342. In fact, IP is often legally added to diesel in small amounts by the refineries, as it helps prevent the diesel from waxing (freezing) during the cold winter months inland. Doping diesel with IP, in the long term, is not a good idea and it is also illegal.

Because this type of doping represents a loss of income for SARS, they have introduced a chemical marker into illuminating paraffin sold in South Africa. The marker comes from Authentix, an American company which specialises in brand protection and anti-counterfeiting. This marker is added to IP at a precise concentration once the product leaves the refinery.

It is possible to test for this marker. The test kit is a lateral-flow test kit, similar to those used for testing for Covid or pregnancy. The answer is just a simple yes or no, the marker either was or was not detected. The test kit is very easy to use and takes hardly any time at all. What it cannot tell you is how much IP is present.

It is important to mention that if the IP came from a source that was not marked, for example from across our borders where markers are not used, then no marker will be detected, yet the sample could still be contaminated, but not by enough to fail the other physical tests that are carried out, for example, viscosity, density, and flashpoint.

Further testing is possible, however. The diesel sample can be sent to a SARS-approved laboratory, where they use an instrument called a GC-MS (gas chromatography – mass spectroscopy) that can measure the actual amount of the marker that is in the fuel and, from that, it is possible to calculate the actual amount of IP in the fuel, as the exact concentration of marker that is added is known.

The reason for having two levels of testing is because (at the time of publishing), the lateral-flow test kit costs about R500, whilst the actual percentage test costs around R5500 (more than ten times the lateral-flow test) and has to be outsourced.

Although it is possible to use gas chromatography to look for IP in diesel directly, because of the very similar physical and chemical characteristics of the two liquids and the large number of compounds in each, the process is slow, expensive, not particularly accurate and difficult to carry out.

At the end of the day, as with lubricating oil, keeping diesel cool, dry and clean is a policy that reaps great benefits, and rewards the user with lower operating costs.

About the author

Diagnostic manager John Evans holds a B.Sc. (Chemistry) from Southampton University, UK. He began his career with the Caterpillar agency in Botswana, establishing oil analysis laboratories in Gaborone and Harare. He then moved to De Beers to build oil analysis laboratories on the diamond mines in Botswana. He ran the Orapa laboratory for three years and was responsible for integrating oil analysis into the mine’s maintenance planning system before joining WearCheck in 1989. John has over 40 years’ experience in the oil analysis business and has diagnosed more than two million oil samples. He is involved in diagnostics, customer support, training, R&D, technical writing and managing remote diagnostic facilities for companies running their own oil analysis laboratories. He co-authored a book with Trevor Hunt entitled ‘The Oil Analysis Handbook’.